Paint industry and circular economy. Is it possible?

Introduction

An economy can be viewed as a system that binds society and natural resources in a profound and interdependent way. The natural resources are sustaining human existence, well-being and prosperity and the ruling economy model impacts the global distribution of these resources and opportunities as well as the related consequences. As the population grows and becomes more aware of the limited resources on our planet, the traditional linear economical system is no longer serving as a sustainable and prosperous model. Thus, in order to seek for a new and better ways for management of resources, policy-makers and industries begin to invest in the transition to circular economy. The paint industry among others seeks for a better, more efficient production practice and ways of eliminating the hazardous production waste. Therefore, this blog post explores what is the circular economy and if it is possible and feasible for the paint industry to adopt the circular economy model.

What is circular economy and why does it matter?

The circular economy (CE) is a model where material loops are closed in order to ensure the use of resources to maximise efficiency. The CE model is fundamentally born out of concerns for the unsustainable consumption of the Earth's finite natural resources expressed in such schools of thought as biomimicry, cradle-to-cradle, the blue economy, industrial ecology and performance economy. The CE aims to change the way of producing by changing business strategies and product design, where longer lasting products are favoured over the ones with short product lifetime, meaning that once raw materials are extracted, the use of their value should last as long as possible (a). The CE, when done correctly, contributes to the economic, social and environmental dimensions of sustainable development.

Ellen MacArthur Foundation is currently the leading research organization dedicated to developing and promoting the CE. According to them, the CE is based on principles that are inspired by natural systems. Five principles of the CE are:

- Design out waste.

- Build resilience through diversity.

- Shift to renewable sources of energy.

- Think in systems and cascades (b).

The CE model can work if the production system runs on renewable resources and if all resources used in the production allow for full recycling without quantitative losses. Additionally, CE emphasizes the importance of producing longer lasting products that can be used for increased periods of time thus reducing the need for new products to be manufactured and resources spent (a, b).

The CE strongly focuses on the responsibility of the manufacturers, recognising that early stages of the product design and production processes set the fundament of the further product life-cycle and the impacts associated with it.

The product design improvements result in more durable products that can be repaired, upgraded and remanufactured. In the CE model, products are designed in a way that allows for disassembling and return of valuable components back in the production system. The framework of eco-design principles is fundamental for the CE product design. The CE product design proposes the engagement of manufacturers in taking greater responsibility for the end-of-life stage of products.

The production processes in the CE model must also be designed carefully, focusing on maximizing the efficient use of raw materials and this includes responsible sourcing that recognises the social and environmental factors related to the raw material extraction. Production in the CE model celebrates innovations that allow for symbiosis of different product manufacturing, where the waste from one production cycle can become a resource for another (f).

Circular, linear and reuse economy

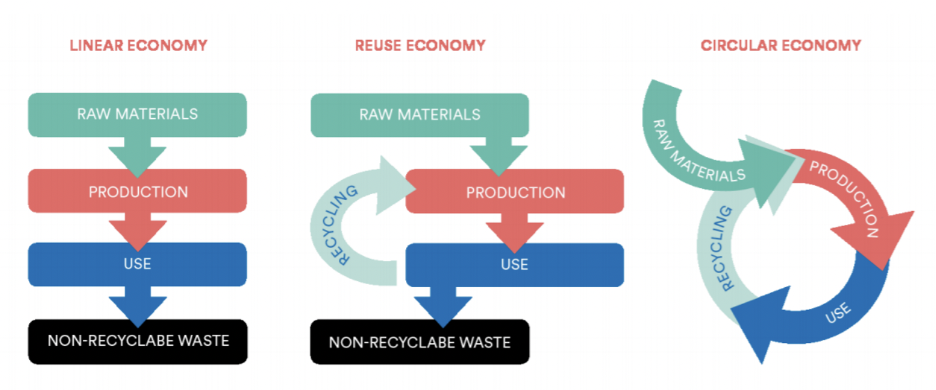

To better understand differences of economic systems and their impacts, circular economy can be viewed in comparison to the linear economy and also the reuse economy model (Figure 1).

The linear economy is the most traditional model of economy that follows the path of “taking, making and disposing,” and as the factor of environmental and social issues becomes more pressing, stakeholders as well as consumers are looking for a better and improved ways of developing and consuming products. To put it simply, in the linear economy model the production has a significant amount of waste, meaning not only wastage of natural resources but also financial losses. Therefore, more and more companies are increasingly recognising the circular economy model to be beneficial and worth investing in. While the reuse economy reduces the burden of waste, it does not close the production loop efficiently enough and a smaller but still significant part of resources (the non-recyclable waste) is sent to landfills. The CE strives to improve the linear and reuse economy model by closing the production loop and limiting any wastage of resources and does so by following the principles of eco-design (c).

Figure 1. Comparison of the linear, reuse and circular economy (Source: A circular economy perspective on sustainable supply chain management: A single case study of the Norwegian paint industry (c)).

Adopting the CE model requires thoughtful product design that is rooted in three core principles of the CE — elimination of waste and pollution, circulation of products and materials and regeneration of nature.

Benefits of the circular economy

The CE model is beneficial for all dimensions of sustainable development and most obviously for the economic and environmental dimensions, where clear improvements in resource inputs and outputs can be observed (Table 1). The social dimension, which is not part of the topic for this blog post, benefits from increased job opportunities the CE model provides, as well as from fair and sustainable raw material sourcing, positively affecting local communities around the world (d).

Table 1. Benefits of the circular economy (Source: Circular Economy: The Concept and its Limitations (d))

| Economical | Environmental | |

| INPUT |

|

|

| OUTPUT |

|

|

Circular economy in the European Union

The European Union (EU) development and industrial strategy prioritizes transition to the CE complimenting the EU goals of establishing low-carbon, resource-efficient and competitive economy.

Multiple legislation initiatives are developed in the EU with the goal of establishing and monitoring the transition to the CE, the most significant being the Circular Economy Action Plan that is one of the building blocks of the European Green Deal action plan which aims to ensure that the EU becomes carbon-neutral by 2050 (e, f, g).

This action plan includes specific targets in order to achieve the transition to the CE model:

- Improving product durability, reusability, upgradability and repairability, addressing the presence of hazardous chemicals in products, and increasing their energy and resource efficiency.

- Increasing recycled content in products, while ensuring their performance and safety.

- Enabling remanufacturing and high-quality recycling.

- Reducing carbon and environmental footprints.

- Restricting single-use and countering premature obsolescence.

- Introducing a ban on the destruction of unsold durable goods.

- Incentivising product-as-a-service or other models where producers keep the ownership of the product or the responsibility for its performance throughout its lifecycle.

- Mobilizing the potential of digitalisation of product information, including solutions such as digital passports, tagging and watermarks.

- Rewarding products based on their different sustainability performance, including by linking high performance levels to incentives (g).

Currently leading EU countries that work toward establishment of the CE are Germany, Belgium, Spain, France, Italy, the Netherlands, which logically correlates with the largest economies of the EU (e).

Further reading on circular economy:

- Ellen Macarthur Foundation

- Circular economy action plan

- Closing the loop - An EU action plan for the Circular Economy

References:

Paint industry and circular economy

Paint manufacturing process involves the use of a wide range of raw materials and with the ongoing goals of sustainable development and transition to the CE, the coating industry is no exception. There are two main ways how the coating industry can participate in the CE, where the simplest way are recycling of waste paint and the more advanced involves re-designing and improving the manufacturing process as a whole, creating closed loop production systems that run on renewable energy sources and involve sustainable material sourcing. Recognising that re-designing a production system is something that may take a long time to become widely implemented, this blog post will further explore the possibilities that paint reusing and recycling currently offer with mention of the performance qualities of recycled paints.

Considerations for paint recycling and reusing are inspired by acknowledging of not only the fact that the resources of the planet are finite but also the impact that life cycle of paint has on the environment. Regarding carbon footprint of paint life cycle, the largest impact accounts for the disposal of paint and second largest accounts for the manufacture of raw materials. Therefore, paint reuse and recycling allows for elimination of more than 50% of the environmental impact from the paint life-cycle (l).

Benefits of paint recycling include:

- Financial and environmental gains since paints do not go to landfills.

- Reduced chemical pollution harming soil and aquatic life means less burden on global food systems.

- Increased environmental awareness and sense of responsibility among community members.

- Cost savings for manufacturers and local governments.

- New opportunities for job creation and support of community initiatives.

Paint waste is a chemical waste that can fall in the hazardous waste category. Most decorative paints fall in one of the following two categories — water-based (latex, vinyl, acrylic) and oil-based paints (alkyd, polyurethane, varnish). Disposal of old or unused paints can often require payment for disposal of hazardous waste, depending on the local municipality policies. Therefore, it could serve as additional motivation, apart from the environmental considerations, to save money and find ways to donate paint to a local reusing or recycling programme (h).

Paint reusing and recycling

Paint reusing and recycling are initiatives that allow for significant reduction of raw resource and energy requirements for paint manufacturing offering environmental and economic benefits.

All water-based and latex paints can be recycled in either new paint products or other commodities such as cement. Oil-based paints can be used for power generating at energy plants.

Paint reusing initiatives allow for a second life for unused paints. Due to the modern paint formulation, average shelf life of decorative paints can last up to ten years. This allows people to donate and give away their unused paints to someone who might still find them useful.

There are local initiatives, such as Rediscover Paint in Ireland that collects the unwanted paints, filters and remixes them into new paints. Such initiatives allow for reduction of the burden of hazardous paint waste and offer a very affordable price for purchasing of reused paint (j). Even large coating manufacturers, such as Dulux, participate in the paint reusing and recycling, sponsoring community initiatives that work towards reduction of paint waste and offering usable coating resources to those in need.

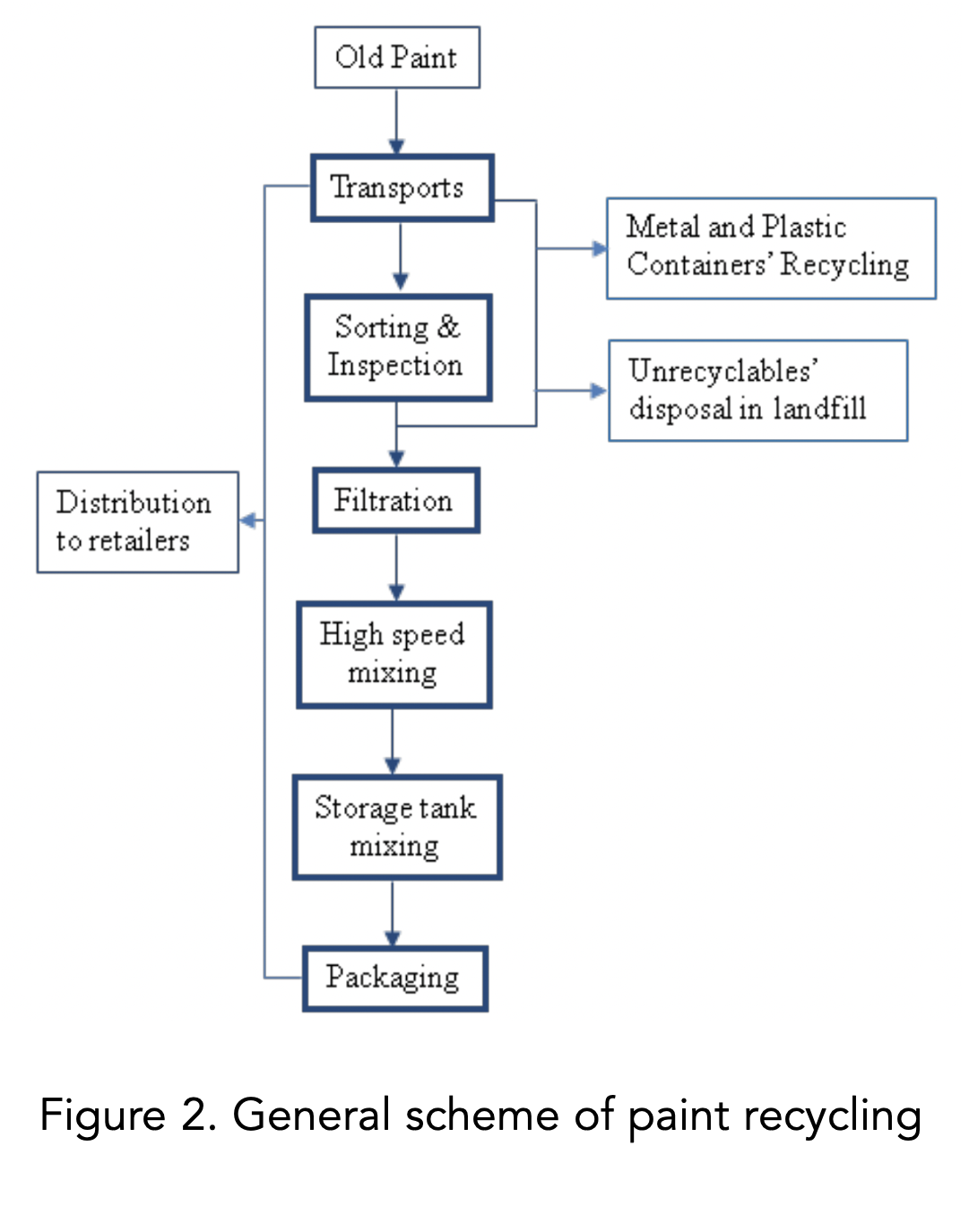

To illustrate the process of paint recycling, we can follow the research done by I. Dunmade in the Mount Royal University in Canada, where the paint recycling process by a single company was analysed and compared to the alternative of sending paint waste to landfill. The analysed company recycles latex paint and produces 60 000 litres of recycled paint monthly.

In research a roadmap of paint recycling (Figure 2) is described, where firstly the old and waste paints are transferred from municipalities to the company’s recycling facility, where further sorting and inspection of paints takes place, dividing them into three categories — oil-based paint, reusable latex paint and non-reusable latex paint. The non-recyclable paint is disposed of in landfill, while the metal and plastic containers are compressed and transported to be recycled separately as plastic and metal waste. The recyclable paints are divided by colour and mixed at high speed. After the first mixing paints are filtered to remove particles and mixed again in the storage tanks after which paints are packaged and distributed to retailers (i).

The above mentioned example is one of many and by no means a perfect model for implementation of the CE, but it illustrates that paint recycling is possible and is indeed implemented efficiently. As the research indicates, the largest environmental contribution paint recycling has is not that of raw material sourcing but that of transportation and distribution.

Recycled paint quality and performance

Recycled paints just as other coatings require compliance with the industry standards, such as pH, viscosity, glossiness and coverage. Some environmental labels, such as the Green Seal, have even developed specific performance standards for environmentally safe recycled paints, ensuring that the coatings awarded with the label are performing equally well as other commercially available coatings. Publications regarding the performance of recycled paints show positive conclusions, therefore inspiring the wider support of recycled paint application over virgin paints (k, m).

References:

Closing

Transition to the CE is currently a priority of the European Union in order to meet the sustainability goals regarding reaching carbon neutrality by the 2050. Due to the pressure from the increasingly aware consumers and policymakers, paint manufacturers, among others, work towards innovative ways of changing the old production models into more sustainable ones. The coating companies all over the world are implementing steps towards transition to the CE, starting with the basic task of tackling waste paint and reducing the required supply of raw materials. This is done by waste paint collection programs and establishment of waste paint recycling into new products. Although gaining momentum, the global coating industry still has a long way to go until it can successfully establish its role in the CE. Recognising the inevitability of the CE, the consumer demand and awareness as well as government and manufacturer support for the innovative circular production systems can ensure that such transition is to happen sooner rather than later.

Author: written by Anse Romančuka, edited by Linda Kikuste

Community thoughts

(No subject)

h) Management of Paint and Paint Related Materials

i) Recycle or Dispose Off? Lifecycle Environmental Sustainability Assessment of Paint Recycling Process

Etc.

Thanks

Facebook

Facebook

Linkedin

Linkedin

Google

Google